What is Soil in Food Processing?

Soil is unwanted matter on the surface of an object that needs to be clean. Soils remaining on food processing equipment are nutrient sources for microorganisms which could result in food safety incidents.

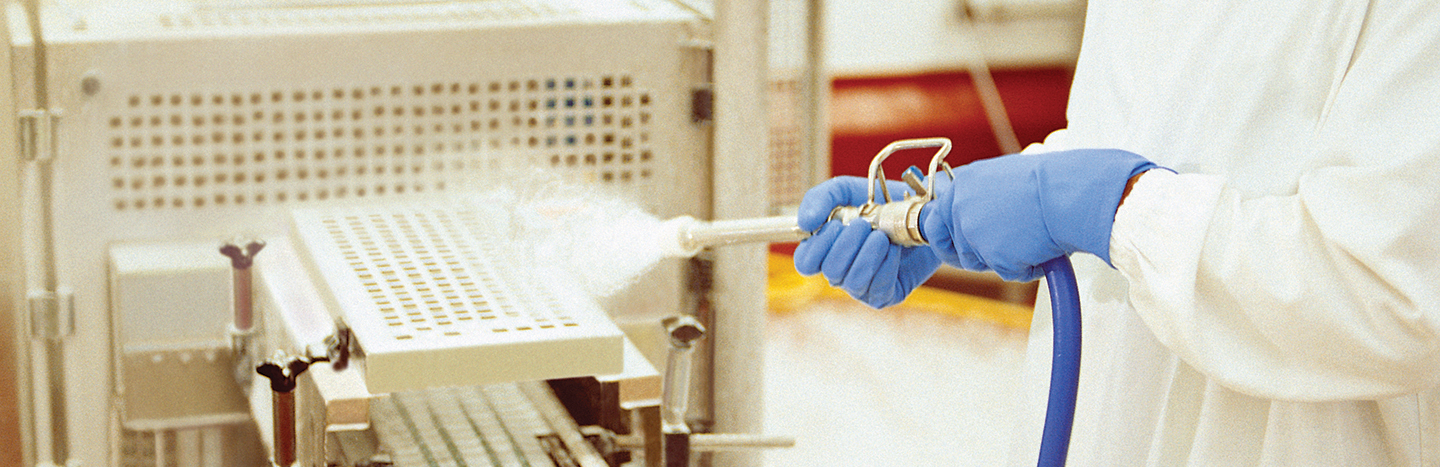

Soils are best identified by characteristics that provide information on how they may be solubilized. Visible soil is classified according to its solubility in water, alkali, acid, surfactant solution or, none of the above. Soils such as sugar and some inorganic compounds can be dissolved and washed away with water. Additionally, the greater part of food soil can usually be suspended in water and simply removed by the force of a water spray.

Soils remaining on food processing equipment are nutrient sources for microorganisms which could result in food safety incidents

Any soil that is not directly soluble in water and is not removed with water pressure will be left behind as a deposit or film. Most films are tightly bonded to surfaces and water sprays as high as 400 psi may be unsuccessful at completely removing the film. In these instances, a detergent must be used. The purpose of detergent is to interact with the film and remove it, either through a chemical or a physical reaction.

Common Soils and How to Remove Them

Protein Soils

Proteins are long chains of different amino acids. All amino acids contain carbon-nitrogen bonds (C-N). Protein soils from milk, eggs, and meat can be solubilized and removed from a surface by a chlorinated alkaline detergent.

How does a chlorinated alkaline detergent remove a protein film from a surface? Chlorinated alkaline detergents contain sodium hypochlorite (NaOCl). NaOCl is an oxidizer which chemically reacts with the C-N bond; it breaks the protein apart and solubilizes the components.

Description:

A blue or rainbow colored film having a varnish like appearance.

Probable Causes:

- Use of a non-chlorinated detergent

- Inadequate pre-rinse

- Intermittent cleaning

Procedure for Removal:

- Use a chlorinated detergent at sufficient strength to maintain 60 PPM available chlorine throughout the wash.

Mineral Deposits

Depending on the process, mineral deposits will take various forms. They are commonly referred to as beerstone, milkstone or waterstone. The composition of these deposits will vary. Some, such as waterstone or hard water scale, are simply the chemical compound calcium carbonate (CaCO3) and can be quickly removed with an acid detergent. Others are more complex matrices of organics and minerals that require a strong chelant or alternating alkali and acid detergent washes.

Description:

White, grey or yellowish deposits, sometimes gritty.

Probable Causes:

- Minerals settling out of water

- Minerals reacting with substances in beer, milk or meat and then settling out

Procedure for Removal

- Either wash with an acid detergent or wash with a detergent containing a strong chelant

- Alternating acid and alkaline washes may be required

Fats and Natural Oils

Fat from animal sources such as milk, poultry, and other meats quickly adheres to surfaces. Natural oils, such as terpenes, that impart flavor to beverages, also adhere to surfaces and act much like fats.

Fats are triglycerides. As such, caustic (NaOH) will chemically break them apart. Cleaning above the melting point of the fat or oil with a hot caustic based detergent is the most effective method of removing fats and natural oils. Generally, this temperature is above 120˚F (49˚C).

Sometimes surface films cannot be seen but there is visible evidence that a film is present. It is important to bear these indicators in mind to help determine if a surface is clean. Beaded water on a surface is usually proof that a surface film is present and that the surface is not clean. If water sheets evenly from the surface, or a water break free surface is present, then the surface is clean.

Description:

A greasy, oily sometimes white film on which water will form into beads.

Probable Causes:

- Low wash temperature (most common)

- Inadequate/low concentration of detergent

Procedure for Removal

- Wash with a hot alkaline solution.

Lubricating Greases and Oils

Lubricating greases and oils cannot be solubilized by either acids or alkali. They can be melted by hot water or steam but usually a thin film is left behind. Surfactants are surface-active compounds which help emulsify greases and oils. Detergents built with surfactants will break greases and oils into small globules which are soluble in water or can be suspended in water. Most dust and dirt contain some oily material which makes using a detergent formulated with surfactants the best choice.

Description:

Black and/or greasy film.

Probable Causes:

- Oil and dirt from manufacturing

- Over greasing of equipment

Procedure for Removal:

- Wash and brush with hot foaming alkaline detergent.

Other Soils and How to Remove Them

Carbohydrates (Sugars and Starches)

Description:

Clear to brown sticky films.

Probable Causes:

- Inadequate pre-rinse

- Intermittent cleaning

Procedure for Removal:

- Wash with a hot alkaline detergent.

- Check the sanitation program.

Surfactant Film

Description:

Blue film

Probable Causes:

- Poor rinsing of detergent

- Overuse of detergent

Procedure for Removal:

- Wash and ensure rinse is adequate (all foam is gone).

- Check concentration.

Gasket (Rubber Film)

Description:

Black streaks which at times may be sticky.

Probable Causes:

- Aged gaskets

- Overuse of chlorine sanitizer

Procedure for Removal:

- Wash with an acid detergent and change gaskets.

Food Stabilizer Films (Gums and Esters)

Description:

White, sometimes streaky film.

Probable Causes:

- Inadequate pre-rinse

- Improper detergent selection

Procedure for Removal:

- Wash with hot alkaline, surfactant detergent.

Iron Deposits

Description:

A red, brown or black film.

Probable Causes:

- High iron in the water supply

- Low pH of incoming water

- Iron corrosion issues

Procedure for Removal:

- Wash with an acid detergent and address the source of iron.

Silica Films

Description:

White or grey glaze on equipment.

Probable Causes:

- Silica from incoming water (most common)

- Poor cleaning

Procedure for Removal:

- Consult your hygiene supplier: need to clean with special acid.

Etching

Description:

Pitting, usually with white deposits on and within pits.

Probable Causes:

- Improper use of chemicals

- Aggressive water

Procedure for Removal:

- Re-polish and passivate surface.

Other Influences Affecting Soils Deposits and Removal

Heat

Many processes in the food industry require heat; for example pasteurization, cooking or frying. Soils that are heat set (formed on a heated surface) are usually more difficult to remove than soils that are cold set (formed on a surface at room temperature or lower). The reason is heat denatures and chemically decomposes the soil.

A heat set soil has lost some of its chemical handles and will not quickly react with acid or alkaline detergents. More aggressive cleaning is usually required to remove heat set soils.

Surface Irregularities

The condition or roughness of the surface will influence soil deposition. Unevenness and surface irregularities offer niches for soil deposits to adhere to.

Having a Comprehensive Sanitation Program for Effective Soil Removal

A well-designed sanitation program should provide both preventative and corrective measures for managing soil deposits in food processing. The program should also be regularly reviewed to ensure the required food safety standards are continuously being met. For example, changes in personnel, equipment breakdowns/changes, or changes in the water characteristics, could reduce the effectiveness of the cleaning chemistry and lead to the formation of a film or deposit.

Diversey's cleaning and sanitizing products have been developed to help customers exceed food safety standards throughout the facility. Our Knowledge-based Services - CIPCheck, OPCCheck and SecureCheck - go one step further by evaluating the efficacy of current cleaning chemistry and sanitation procedures while uncovering optimization opportunities. Contact us for further information